Pile Driving Pontoon

One of the important techniques in marine construction is the pile driving process. Pile driving is a critical method used in marine construction and other ground improvement projects to establish a solid foundation for structures. This process is carried out to increase the load-bearing capacity of the structure and enhance its interaction with the ground.

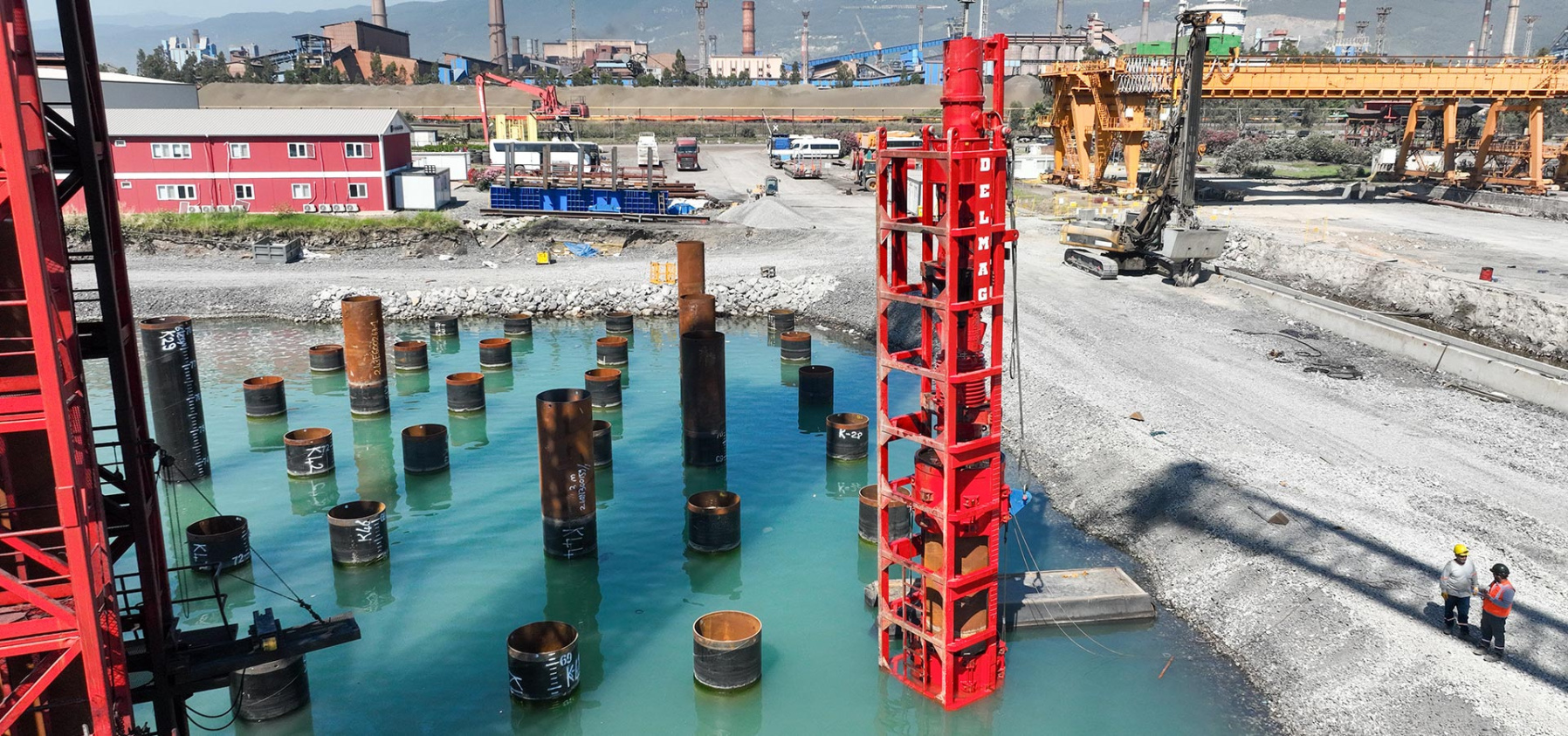

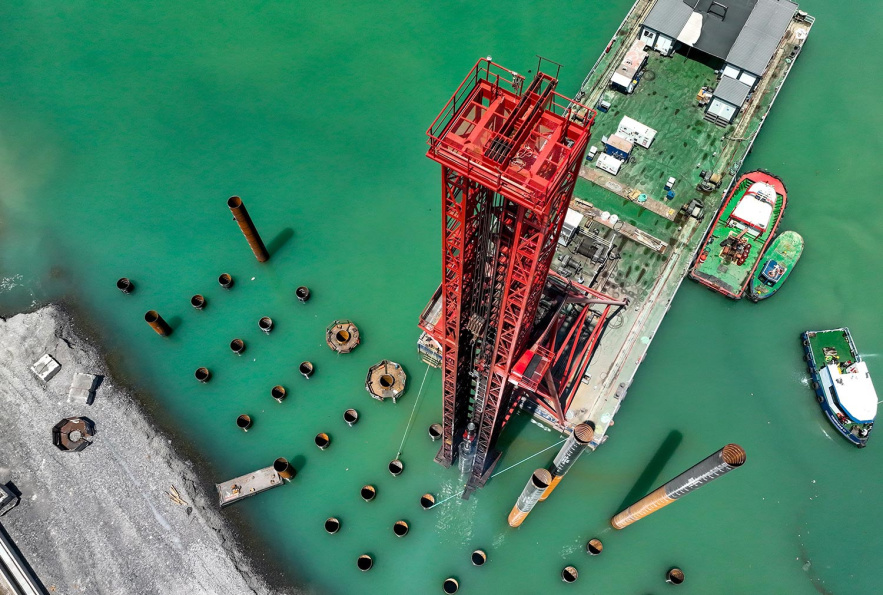

Special equipment is used for pile driving, with pile-driving pontoon being one of the most commonly used machines. These machines apply significant force to drive piles to the desired depth. A pile-driving pontoon is a specialized marine vessel designed for the installation of piles, a fundamental component in various marine and construction engineering projects. Piles are structural elements driven into the ground to provide foundational support for structures such as bridges, piers, offshore platforms, and coastal protection systems. These vessels play a crucial role in ensuring the stability, durability, and safety of such infrastructure in challenging marine environments.

Various types of piles can be used depending on ground conditions. Typically, piles made of concrete, steel, or composite materials are preferred. The type of pile is determined based on the soil structure and load-bearing capacity.

The most important part of a pile-driving pontoon is its heavy-duty crane, equipped with a special pile hammer or vibratory hammer. These hammers have the capability to deliver significant force, allowing efficient driving of piles to the seabed's required depth.

The pile is driven into the ground by the hammer’s force. While concrete or steel piles are generally installed using heavy machinery, hydraulic systems may also be employed in some cases. During the driving process, it is essential to ensure that the piles are placed properly and reach the desired depth.

Once the pile is fully driven into the ground, the top of the pile is typically secured with a concrete platform to evenly distribute the load that the structure will bear. At this stage, the spacing and alignment of the piles are critical.

After the driving process is complete, the load-bearing capacity of the piles is tested. The accuracy of their interaction with the ground is checked to ensure the long-term safety of the structures.